We have built five production bases in Zhongshan, Foshan, Yiwu, Ji 'an and Xinyu, total construction area is more than 3,000,000 square meters.

-

Zhongshan Production Base

-

Foshan Production Base

-

Ji'an Production Base

-

Xinyu Production Base

-

Yiwu Production Base

-

Zhongshan

Production Base

Focus on the production of a full range of LED light source devices and power supply manufacturing

-

Foshan

Production Base

Has the most complete range of traditional light source products, and provides high-end customized services for various LED lighting products

-

Ji'an

Production Base

Specializing in the production of full LED light source device semiconductor materials and LED full color display

-

Xinyu

Production Base

Set R & D, production, sales as one of the large comprehensive professional circuit board manufacturing enterprises

-

Yiwu

Production Base

Specializing in the production of LED lighting fixtures and LED filament lamps, semiconductor materials and supporting hardware materials

8 R&D Laboratories

Total eight laboratories have been established, total of more than 20,000 employees, including more than 3,000 R & D personnel.

-

Zhongshan Central Laboratory

-

Xinyu R&D Laboratory

-

Mulinsen Lighting Laboratory

-

Ji'an Production Base

-

Ledvance Testing Laboratory

-

Xinyu Central Laboratory

-

Ledvance Laboratory

-

Mulinsen Laboratory

- LED CIRCUIT BOARD

- LED DRIVER CHIP

- LED EPITAXIAL CHIP

- LED LAMP PACKAGING

- LED MODULE

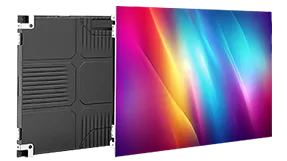

- LED DISPLAY SCREEN

LED EPITAXIAL CHIP

LED light chip, is the core component of the LED device, its main function is to convert electrical energy into light energy

LED LAMP PACKAGING

The most advanced fully automated production equipment in the world, LED packaging lamp sales rank No.1

LED DRIVER CHIP

Integrated circuit chip integrated solution, providing constant current drive, line drive, logic control and other LED display solutions

LED CIRCUIT BOARD

Global LED related industry PCB core supplier, PCB, FPC, MPCB all types of products monthly comprehensive capacity of 1.5 million sqm

LED MODULE

With the industry's advanced fully automated Germany Siemens SMT machine 200, LED module monthly product 1 million pieces

LED DISPLAY SCREEN

Give full play to the advantages of intelligent manufacturing, provide OEM/ODM services for the industry big brands for many years

-

Solder Paste Printer

Solder Paste PrinterSolder Paste Printer

Equipment precision control: ±18um

Printing speed: 50mm/s

Scraper pressure: 4~9Kg -

Reflow Welding

Reflow WeldingReflow Welding

ERAS10 Thermal zone in Germany

Temperature control accuracy :+1°C

Daily temperature curve test -

Patch Machine

Patch MachinePatch Machine

Control accuracy of the placement machine +25um

PCB deformation mounting pressure automatic correction function -

Automatic Assembly

Automatic AssemblyAutomatic Assembly

Automatic bottom shell,PCB assembly

Automatic locking screw,torque 0.6kg

Reverse alarm of visual identification missing lock

-

SPI Check

Equipment resolution, 15um

Check standard: CPK≥2

IPQC spot check once in 4H

-

AOI Check

Device resolution: 17.5um

component offset ≤0.1mm

The first 5 Pcs are 100% confirmed

-

Automatic Lighting

Fully automatic light visual judgment

Test screen W/R/G/B, obliquesweep, gray level, dead light,dark light

-

Module Aging

The entire screen of the dedicated area is aging

Aging time: 12 hours +

White and black aging alternately, confirmed by specially-assigned person

-

PCB—Line Width and Line Distance

P1.2 minimum line width :0.088mm

P1.2 Minimum line distance :0.099mm

IC is 1.8mm away from PCB side

PCB drilling control

-

AOI Check

Before design, the lamp PADneeds to be compared with thestandard gallery

Different lamp beads are designed differently to avoid the dark side

-

Bottom Shell Matches PCB

The front electrolysis,avoid socket interference,24mm safe distance

The bottom shell appearance design is novel

-

Surface Temperature

LED driver IC layout optimization law -> discrete arrangement

Avoid area color differences

Super Factory Customized Service Process

We are large source factory, provide you professional LED display OEM/ODM service

-

Demands & Inquiry

26 LED years of experience will understand your needs

01 -

Quotation & Budget

Professional technicians will provide you with options

02 -

Project Assessment

Give optimization suggestions, and save 80% of your time

03 -

After-sales

We believe that after-sales is the beginning of all after

06 -

On Time Delivery

Strict internal management procedures, strict quality control

05 -

Optimized Solutions

Provide optimal solutions for your project, considering all details

04

Corporate Partners

We provide you professional service of big brands

GET IN TOUCH WITH MLS

Please contact us if you have any needs